“There’s a lot of promise with the nanoparticle systems we’ve been developing”

Imagine a world where cancer treatment is not only effective but precise, targeting tumors directly without harming healthy cells. This vision is becoming a reality thanks to the groundbreaking work of MIT engineers, particularly Institute Professor Paula Hammond and her talented team.

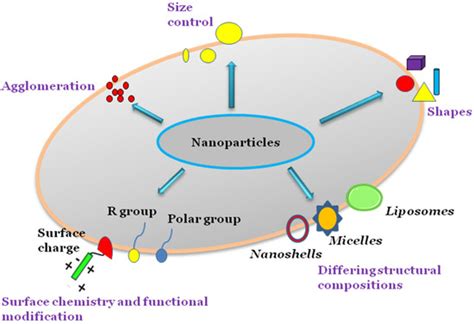

For over ten years, Professor Hammond has been at the forefront of developing nanoparticles designed to combat cancer. These tiny particles, created using layer-by-layer assembly techniques, have shown remarkable efficacy in fighting cancer in laboratory mice. Now, with their sights set on human trials, the researchers have devised an innovative method for mass-producing these game-changing nanoparticles.

In a recent study published in Advanced Functional Materials, Hammond and her colleague Darrell Irvine unveiled a new manufacturing technique that allows for the rapid production of larger quantities of nanoparticles. Their goal? To bring this cutting-edge technology from the lab to real-world applications on a commercial scale.

“Ultimately, we need to be able to bring this to a scale where a company is able to manufacture these on a large level.”

The key breakthrough lies in streamlining the nanoparticle production process. While their original method involved time-consuming steps like centrifugation after each layer application, the team sought more efficient ways to scale up production. Enter microfluidic mixing devices—a sophisticated tool that enables precise layering of polymers on nanoparticles as they flow through microchannels.

This novel approach eliminates the need for labor-intensive purification steps between each coating, significantly reducing production time and costs. By leveraging good manufacturing practice (GMP) principles mandated by the FDA for product safety and consistency, Hammond’s team has paved the way for seamless translation from lab experiments to clinical trials.

“With the new approach… We can create an innovation within… quickly produce it.”

One standout feature of these engineered nanoparticles is their ability to carry drugs directly into cancer cells while sparing healthy tissue—a remarkable feat that holds immense promise for targeted therapy. The team’s recent success in producing interleukin-12-coated particles showcases their potential in activating immune responses against ovarian tumors.

These specialized nanoparticles not only bind specifically to cancerous tissues but also trigger localized immune responses within tumors—potentially leading to tumor regression and even remission in preclinical models. Such tailored therapies could revolutionize how various cancers are treated in the future.

Looking ahead, Hammond and her collaborators are exploring avenues for commercialization through partnerships with MIT’s Deshpande Center for Technological Innovation. While their initial focus remains on abdominal cancers like ovarian tumors, they envision broader applications across different types of cancers such as glioblastoma—an aggressive brain cancer with limited treatment options.

By securing funding from prestigious institutions like the U.S. National Institutes of Health and garnering support from research grants at MIT’s Koch Institute, this pioneering work stands poised to redefine cancer care with its precision medicine approach.

Leave feedback about this